• Mr. S. L. Agarwal, Founder and Managing Director, commenced Websol Energy System Limited.

• First organization in India to begin manufacturing of conventional solar cells with 1MW manufacturing capacity.

• 4’’ diameter waters used and reclaimed from semiconductor industry Module which was 40 Wp.

• Enhanced production to 6’’ wafers and modules up to 95 Wp.

• Achieved quality certification from ISPRA IEC 61215 standards.

• Expanded production to 8’’ wafers.

• Module output increased to 125 Wp for type W1000.

• Production capacity increased to 3 MW.

• Secured international certification for W1000 as per IEC 61215 standards.

• Received UL 1703 listing for W900 type modules.

• Secured UL1703 listing for W1000 type modules.

• Enhanced capacity from 3MW to 5MW and began producing 160/190Wp modules.

• Increased capacity from 5MW to 10MW.

• Commenced commercial production of W1600 and W2000R type modules.

• Achieved TUV safety class II certification for W2000 and W1600 type modules.

• Industrial site in SEZ Falta, West Bengal was finalized.

• Expanded total installed capacity to 20 MW.

• Launched three new products, including W2000R type module.

• Achieved international certifications, IEC 61215 and IEC 61730, for 180/220Wp modules.

• UL and CSA listing were obtained for 180/220Wp modules.

• Enhanced cell efficiency by more than 16.5%.

• Established a state-of-the-art production facility in Falta Special Economic Zone, West Bengal.

• Upgraded wafer size from 125x125 mm to 156x156 mm, increasing module power output to 290W.

• Enhanced total installed capacity to 60 MW.

• Enhanced total installed capacity to 120 MW.

• Formed a two-year tie-up with Renesola (China) for cell and module production.

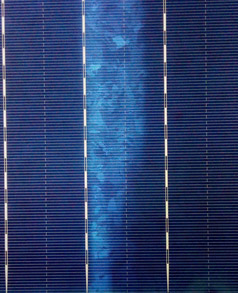

• Began processing quasi-mono wafers.

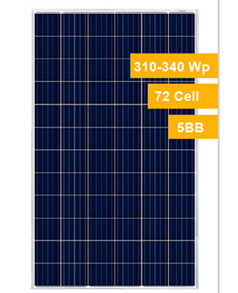

• Installed a new texturizing line to produce cost-effective multi-crystalline solar cells.

• Enhanced installed capacity to 180 MW.

• Installed new process machines in the cell line to optimize efficiency, reaching an average efficiency of 18.30%.

• Began trials for 4BB cells.

• Installed a new high-productivity printing line along with PECVD, Diffusion, and Inox machines.

• Further enhanced capacity to 240 MW.

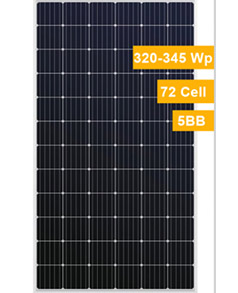

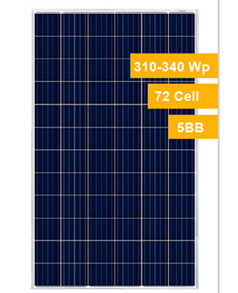

• Commenced 5BB cell production with an advanced cell printing line.

• Transformed the existing module line into a fully automated, high-tech 250 MW module line.

• Installed solar power facility of 120KW, leading to the production of 1,00,000 units, (reducing CO2 emissions by roughly 97,659 kg yearly) connected to a grid in April 2017.

• Achieved the highest cell and module efficiency by fortifying capacity, tuned machines and processes.

• Reduced process chemicals and advanced materials use like paste and screens, enhancing both productivity and quality substantially.

• Reduced solar cell manufacturing cost by 8% due to lower raw material costs, process improvements, productivity optimization, and shop-floor energy saving.

• Increased wafer size from 157x157mm to 158.75x158.75mm multi-crystalline, enhancing 7 watts in 72-cell module.

• Achieved front Ag paste saving with increased printing throughput, leading to enhanced cost-effectiveness by 10%.

• Reached the highest cell line production capacity.

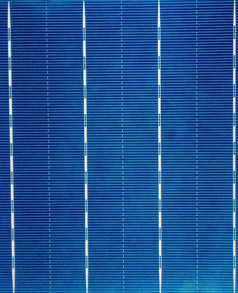

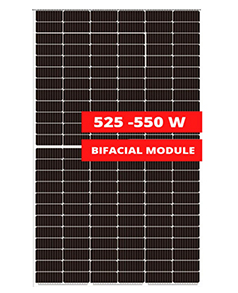

• Adopted advanced Mono PERC technology to stay in line with global standards to produce cells in 182 mm and 210 mm square format.

• Upgraded solar PV modules to 540 Wp and 660 Wp.

• Marked the commercial start of the new 600 MW Mono PERC cell line with the ability to produce cells with 23%+ efficiency.

• Continue to uphold ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications.

• Preparing to expand solar cell capacity to 2.4 GW and maintain module capacity at 550 MW in two years.